Tempered Glass Technical Specifications

Tempered glass technical specifications begins with a heat treatment process in which it travels through a tempering oven. The oven is specifically designed to heat the glass to a temperature of more than 600 degrees Celsius. The glass then undergoes a high-pressure cooling procedure called Quenching. During this process, high-pressure air blasts the surface of the glass from an array of nozzles in varying positions. This process lasts only seconds but is expertly timed for the size and thickness of the glass. Quenching cools the outer surfaces of the glass much more quickly than the center forcing the glass to shift internally to pull on its own structure. As a result, the center remains in tension, and the outer surfaces go into compression, which gives tempered glass its strength.

Tempered glass technical specifications begins with a heat treatment process in which it travels through a tempering oven. The oven is specifically designed to heat the glass to a temperature of more than 600 degrees Celsius. The glass then undergoes a high-pressure cooling procedure called Quenching. During this process, high-pressure air blasts the surface of the glass from an array of nozzles in varying positions. This process lasts only seconds but is expertly timed for the size and thickness of the glass. Quenching cools the outer surfaces of the glass much more quickly than the center forcing the glass to shift internally to pull on its own structure. As a result, the center remains in tension, and the outer surfaces go into compression, which gives tempered glass its strength.

The Physics of Tempering

Tempered glass is about four times stronger than annealed, or "regular," glass. Non-tempered glass can shatter into jagged shards when broken. Tempered glass fractures into small, relatively harmless pieces due to the nature of it's internal structure. Because the surface is heated beyond the center, the glass has the dual property of always pulling on it's own structure on the microscopic level.

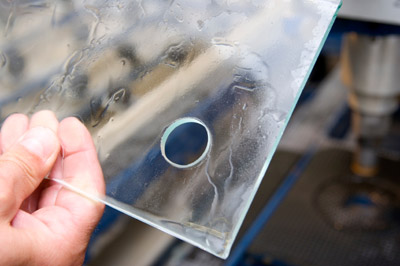

Size Before Strength - Tempered Glass Technical Specifications

To prepare glass, it must be cut to the desired size before tempering. Like the old carpenters advice says, measure twice-cut once. Slightly cracking the hardened surface could tweak the entire structure out of it's balance and shatter. To learn more about tempered glass technical specifications, please give us a call at (855) 237-2063.